For more than a decade, PES has provided value-added construction services for our customers. Our projects can be found on all seven continents and include many construction industry “firsts”—the first floating roof tank for storing oil, the first double-wall LNG storage tank and the first LNG peak shaving plant, among others.

We provide a broad range of field construction services that include modular and conventional (“stick-built”) construction, project management, construction inspection and management, scheduling, welding and quality assurance, plant startups and commissioning, operator training and a variety of other field services. In addition to

new construction work, our projects have included plant relocations, retrofits, disassembly, upgrades, debottlenecking, shutdowns and turnarounds.

Through SMART Modularization, our plug-and-play strategy creates opportunities for innovation, digitalization

and sustainable solutions . One size does not fit all. That’s why we meet each customer’s needs through a range

of execution methods including:

Pre-assembled solutions

– Vendor packaged solutions

– Truckable solutions

– Pipe rack and medium process modules

– Large/Complex process modular solutions

– Mega module solutions

has a fleet of derrick barges, construction and pipelay, and support vessels capable of

transporting and installing complex oil and gas structures such as jackets, topsides and

subsea structures. The fleet is capable of installing pipelines in S-lay, reel-lay and flexlay

from shallow to deep water.

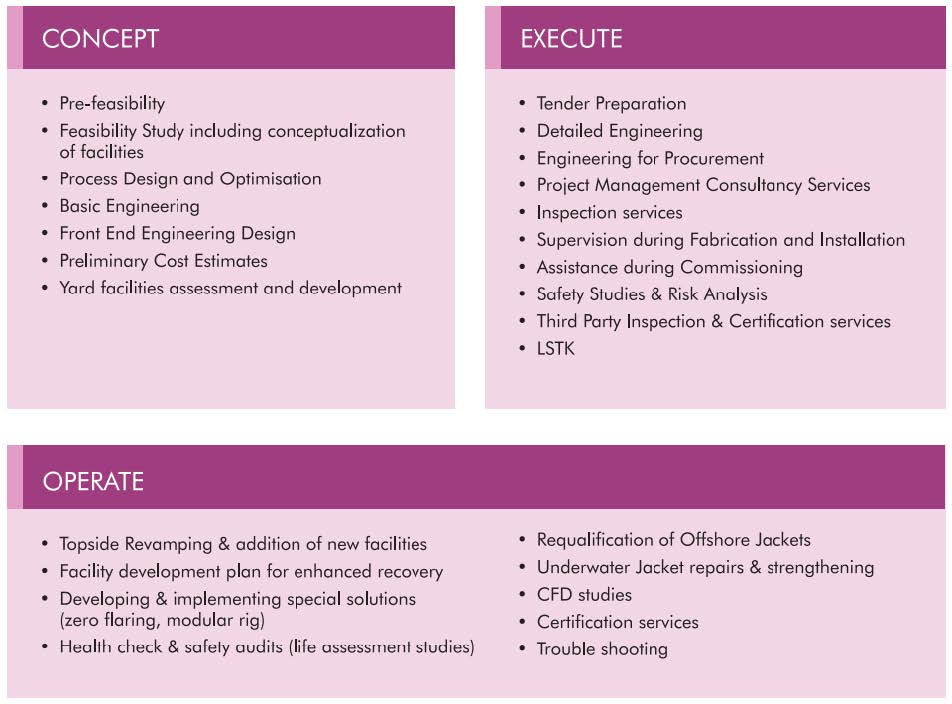

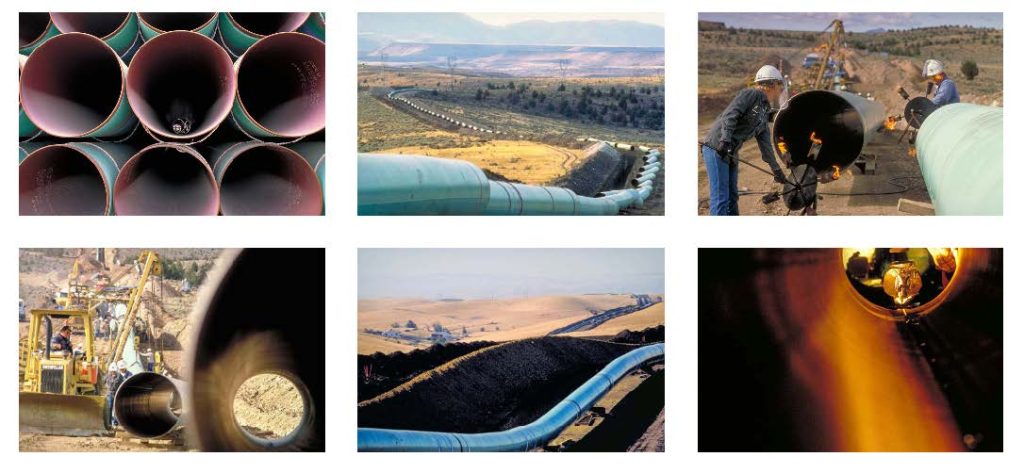

We provide End to End Solution for Design, Develop, Construction, Installation &

Commissioning of Heavy Refinery Oil and Gas Pipelines and do Cross Border

International Projects for Pipeline Laying

PES global project delivery capabilities brings together high-end technical & engineering skills along with

extensivepractical experience in project execution to deliver best in class offshore consultancy services. Our

offshore servicescover the entire gamut of offshore project lifecycle